Understanding Bioprocessing

Published date: 15 Sep 2023

|

Bioprocessing is a branch of biotechnology that involves the use of cells or organisms to produce products through various biochemical processes.

It combines biology, chemistry, engineering, and other scientific disciplines, to develop and optimize processes to produce pharmaceuticals, biofuels, industrial enzymes, agricultural products, and a wide range of other bioproducts.

Want to see our full component range for the Bioprocessing industry? Click here.

Bioprocessing has two main stages - upstream and downstream - to produce these final products.

So, what are they?

Upstream Bioprocessing:

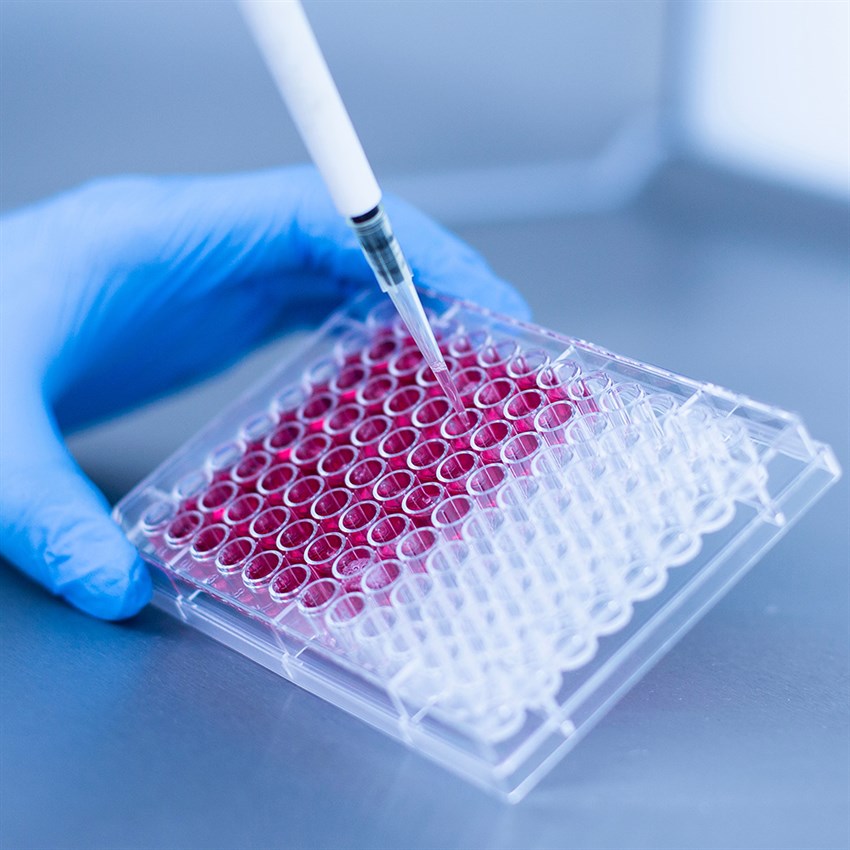

The initial stages of biomanufacturing, encompassing various steps involved in the production of biological compounds and therapeutic molecules. The core elements of upstream bioprocessing include cell line development or growth, cell culture, media optimization, and fermentation in a controlled environment.

The Advantages of Upstream Bioprocessing:

- Higher overall efficiency and profitability through streamlining the early stages of manufacturing.

- Greater control over critical parameters: cell growth conditions, nutrient supply, temperature, pH, oxygen levels, and waste removal.

- Improved product quality and reduced batch to batch variability through control of the manufacturing process.

- Upstream bioprocessing enables rapid development and scalable medical devices. By reducing the time required for cell line development and optimization, the medical device industry can expedite product commercialization and meet market demands more effectively.

Challenges of Upstream Bioprocessing:

- Technical challenges related to maintaining consistent conditions such as ensuring a sterile environment and managing large scale operations.

- Robust infrastructure, automation and quality control measures are essential for successful scale ups. This results in the increase we see with single-use plastic components, as their sterilization and set up times are shorter than with stainless steel.

- Stringent regulatory requirements to ensure product safety and efficiency, and implementing upstream bioprocessing techniques may require additional considerations to meet regulatory standards.

- Initial investments infrastructure, technology, and skilled personnel can be substantial - companies must carefully evaluate the cost benefit analysis and allocate resources effectively.

|

Understanding Downstream Bioprocessing:

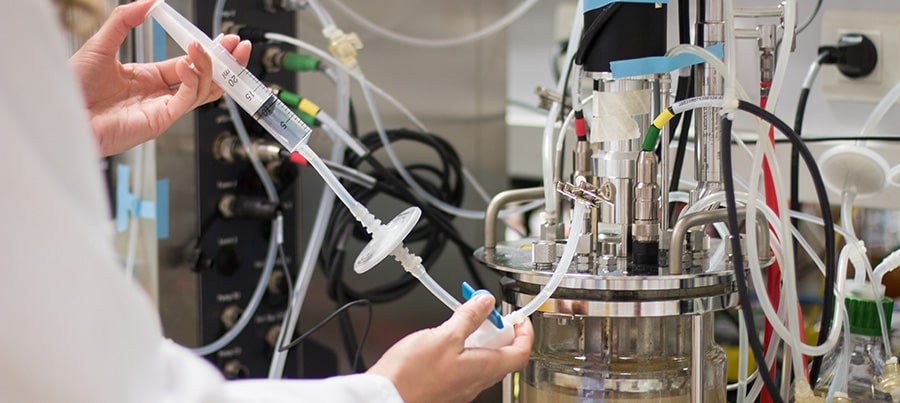

Downstream bioprocessing refers to the purification and isolation of the desired product from a biological source, such as a fermentation broth or a cell culture. It is a crucial step in the production of biopharmaceuticals, enzymes, and other bio-based products.

Advantages of Downstream Bioprocessing:

- Downstream bioprocessing ensures the purity and quality of the final product by removing impurities and contaminants, which is essential for pharmaceuticals and other products where purity is critical for safety and efficacy.

- Allows for concentration and yield improvement through the removal of unwanted components and concentration of the target product.

- Enhances safety and regulatory compliance by maintaining the steps of product integrity.

- Enables separation and purification through techniques such as chromatography (separation by running a solution through a medium) and filtration, additionally ensuring the removal of impurities and contaminants.

- Streamlines the scale-up from lab-scale to industrial-scale production and allows for the recovery of valuable by-products.

- Reduces costs and improves overall efficiency.

Challenges of Downstream Bioprocessing:

- Requires careful and efficient purification methods. The presence of impurities, such as host cell proteins, DNA and viral contaminants adds to the complexity of downstream bioprocessing.

- Developing a robust and scalable purification strategy to create the desired product can also be a major challenge.

- The purification process requires multiple chromatographic separations, filtration, and concentration steps. Each of these steps requires increased costs of production and an increased risk of loss of product.

- Scale-up of the downstream process requires increased challenges in terms of equipment, process, costs and effectiveness.

Key Differences Between Upstream and Downstream Bioprocessing:

- Upstream bioprocessing is concerned with the early stages of biomanufacturing, such as cell culture, fermentation, and media optimization, and is usually done on a much larger scale.

- Downstream bioprocessing, on the other hand, involves the purification and isolation of the desired biomolecules, such as proteins or nucleic acids from the cell culture.

- Both upstream and downstream are critical for the overall success of biomanufacturing.

- Efficient upstream bioprocessing can lead to higher yields and better quality products, while downstream bioprocessing ensures the purity and safety of the final product.

Our Solution

Plastics offer significant advantages over stainless steel when it comes to the convenience of disposal and turn-around time between batches. Stainless steel requires extensive cleaning and sterilization, required after each batch. Stainless steel sterilization requires heat, pressure, and specialized equipment which is time consuming and resource intensive. Additionally, plastics offer the convenience of being disposable which would eliminate the need for full system sterilization. Plastics also reduce the potential of cross contamination, making them an effective and efficient option for the bioprocess market.

To view our full component range, click here.

Components made from Tritan™ copolyester offer many advantages over other thermoplastics. Chief among them is the best-in-class chemical resistance that helps devices retain aesthetic and functional integrity after sterilization, and an outstanding ability to withstand aggressive medical disinfectants, powerful oncology drugs, drug carrier solvents such as DMSO, adhesives, and lipids. Eastman Tritan™ is made without bisphenol A (BPA), halogens or ortho-phthalate plasticizers (DEHP).

Injectech has been using Eastman Tritan™ copolyester in components for years. We consider Tritan™ copolyester an extraordinary material due to its advantages over other thermoplastics.

The inherent properties can eliminate the secondary annealing step required to reduce stress cracking issues in some devices made with polycarbonate (PC). This can reduce processing bottlenecks, improve yield, and reduce overall system costs. Tritan™ copolyester is an ideal material for use in single-use bioprocess applications as it performs well with DMSO and other commonly used carrier solvents. Injectech offers male and female luers, tube-to-tube connectors, filters and valves. Our components are used in bioprocessing filtration, chromatography, and bioreactor/cell culture applications. Injectech components are used to ensure the integrity of the processes, preventing contamination and product loss. Our barbs provide a secure connection with tubing. Injectech’s components come in multiple materials, variations and sizes, allowing our products to work in a wide variety of systems within the bioprocess market.

Leave us your comment

You need to login to submit a comment. Please click here to log in or register.