Services

Injectech has an established reputation for flexible manufacturing. We offer our customers a number of specialized services. We are equipped to manage all stages of project development from design and engineering to verification and validation.

Don't see the fitting you need for your project? Contact us to find out how we can assist you. Along with our established line of plastic barbed fittings, Injectech can also produce custom components to meet your needs.

Providing your project with support from start to finish

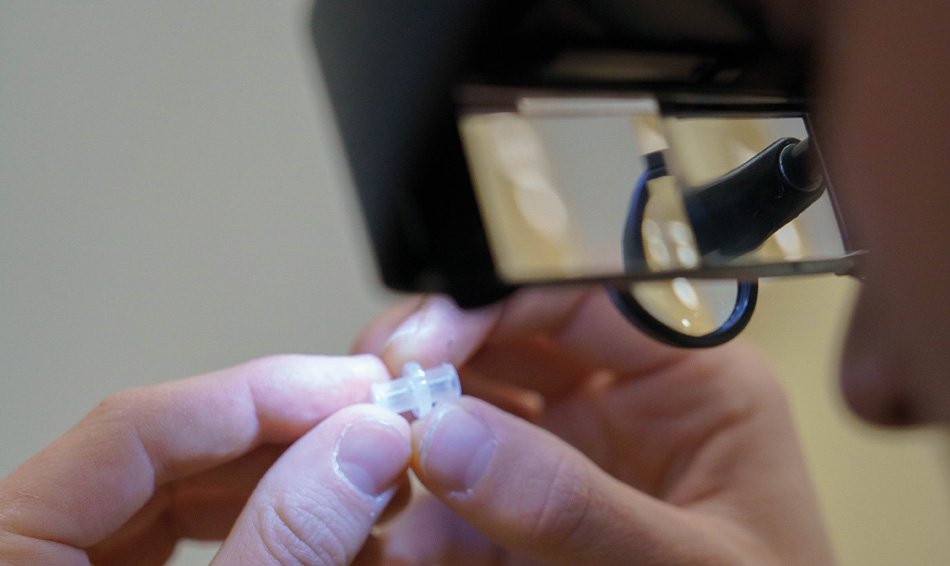

Assembly

Our assembly services include, solvent and adhesive bonding, cleanroom assembly, component sourcing, ultrasonic welding and rapid tube assembly.

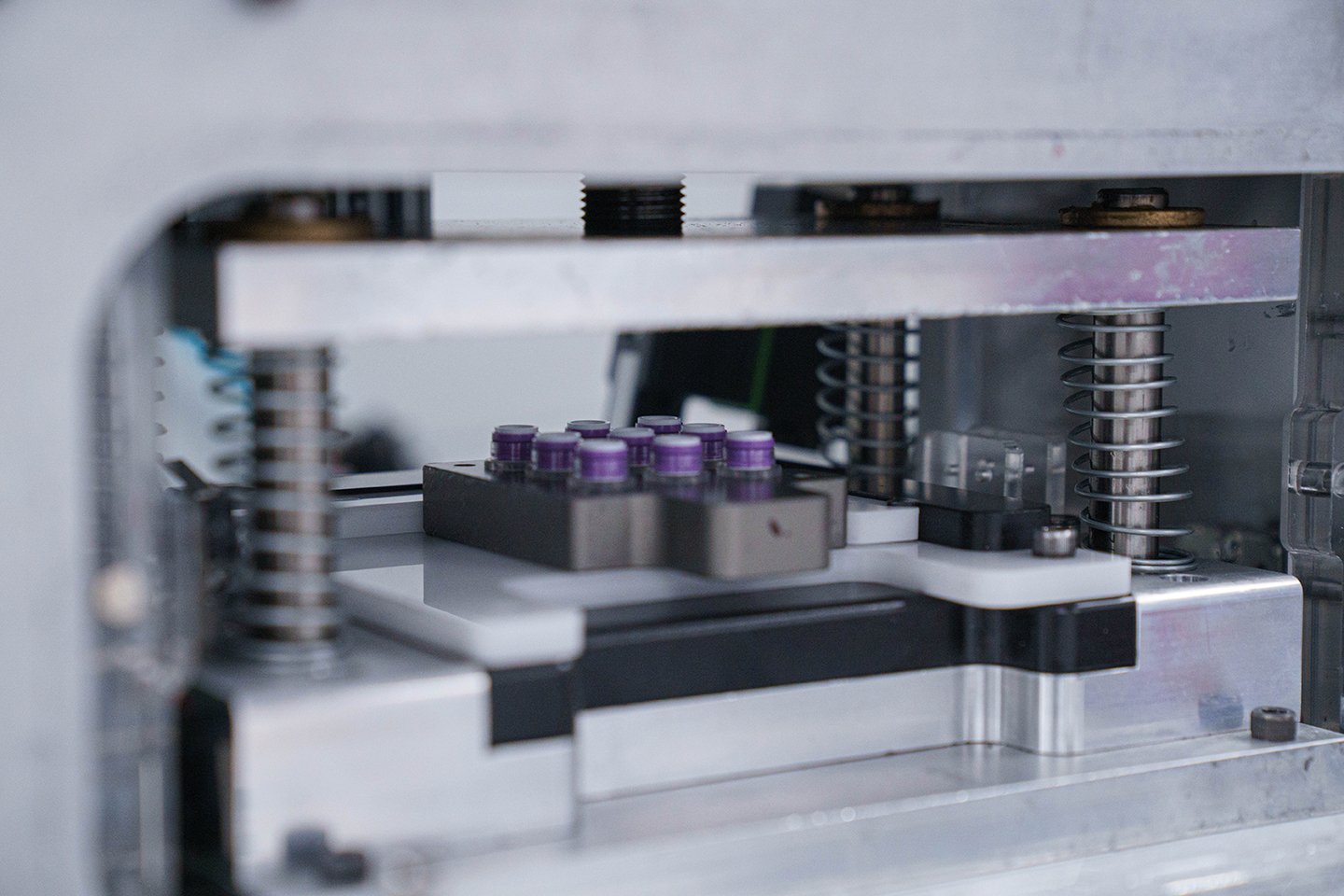

Manufacturing

Our manufacturing services include, lot traceable materials, ISO Class 8 environment, QMS certified to ISO 13485, insert molding, all electric injection presses, automated processes and high temp. processing capabilities.

Custom Design

Our custom design services include, prototype machining and molding, design support and consulting, production molds, and material sourcing. Click the button at the top of the page to find out more.

Engineering

Our engineering services include, custom components, first article inspection reports, initial mold verification sampling, leak and pressure testing, process characterization studies, performance qualification studies, and collaborative verification and validation.

Do you have an idea for a fitting, but our established line of fluid-control components doesn’t fit your needs? Injectech offers custom design and assembly services while maintaining trustworthy customer service to meet your project requirements and timelines.

Our custom services go beyond the manufacture of custom molded components. We provide complete project management services from design to delivery. Injectech’s Product Development Team will collaborate with you to help answer any questions and address any obstacles in the process to ensure the success of your project.